WinHoist® & Sensor os®

PROCESS CONTROL

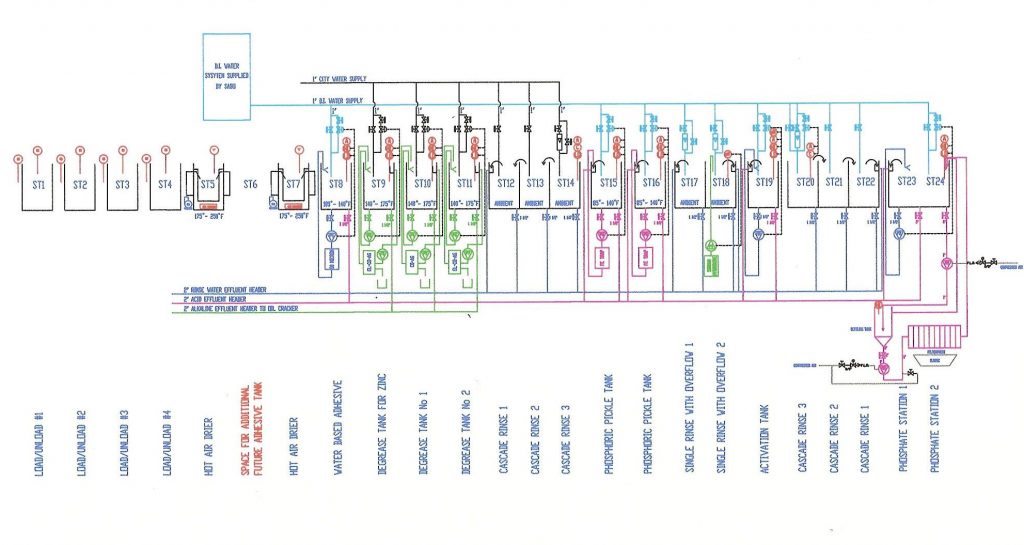

Amsax is the technology leader in process control software. Our proprietary systems (ISO 9001 Certified) integrate all motion and process controls with next-gen intelligence.

The most advanced control system for processing lines & industrial robotics

Our object-oriented random loading software WinHoist® & Sensor OS® enable the most flexible managing of a process line regardless of the number of carriers, stations or process requirements. Over the years our systems have been continually improved for the innovations of modern production.

- Full simulation to run new recipes offline, re-balance a line, or even test new tank configurations.

- Changes can be made in real-time that would take hours to customize in ladder logic.

- Payloads with the same processing recipes do not have to be grouped together (batched) and workflow does not breakdown for critical orders.

Our software unlocks an unmatched degree of control & efficiency, including production tracking, process parameter monitoring

& statistical process control.

Forward Thinking Capability

WinHoist® and Sensor OS® Forward Thinking AI anticipates each carrier’s future moves and constants refines its own internal strategy — incorporating the interplay of other carriers and updating to optimize coordinated motions. This is a critical asset for when a process is interrupted, whether for inspections or power loss; the software remains active and automatic operations can recover and resume immediately based on real-time conditions.

This ability also reduces delays when carriers share zones of travel. The outcome is significant — a payload no longer waits for a hierarchy of obsolete “reservations” to play-out before moving, and consistently makes the best current move to adhere to process specifications. The carriers optimize their motions and act as a team.

Intelligent Systems

- Advanced Random Loading – Eliminates ghost moves and maximizes throughput while recognizing existing payloads and the chemistry in each tank. It even allows manual inspections while simultaneously processing multiple automatic payloads.

- Certified Processing – Each payload is held in a queue until it can fit into the parameters of the protocols for itself without disrupting the payloads ahead in the line.

- Live Adjustment – Allows for real-time scheduling and modification. WinHoist® constantly reassesses which payload in the queue can be processed next and adjusts to user-initiated overrides.

- Additional Practical Advantages – Such as allowing redundant stations to be individually taken offline or elevating priority after a user-defined interval.

Contact

704 California Avenue

Rochester, PA 15074

Phone: (412) 292-0127 or (412) 944-7400

Fax: (724) 201-0051

Email: info@amsaxtech.com